EagleBurgmann international

EagleBurgmann WORLDWIDE

With around 250 locations and 90 serve centers, we are represented in the most important economic regions of the world. The advantages are clear: short paths to our customers, fast response times and a shared language.

Agitator seals optimized for side and bottom entry drives: HSMR34 and SeccoMix R for critical media in ATEX applications

EagleBurgmann has improved the design of its proven HSMR34 and SeccoMix R mechanical seals. The result is even safer and more reliable operation, especially in connection with aggressive, sticky, or viscous media or a high solids content. Both product lines are suitable for any installation situation and are approved for use in all explosive environments according to the ATEX Directive. Their modular design makes them ideal for standardizing seals in the chemical, petrochemical, and food processing industries.

HSMR34 is a double-acting liquid-lubricated mechanical seal. The standard material used is silicon carbide (SiC) in a hard/hard pairing. SeccoMix R is a dry-running double seal supplied with nitrogen and featuring a hard/soft pairing. It is optionally available with a SiC/SiC pairing as well. Both mechanical seals are ideally suited for use in agitators, mixers, kneaders, dryers, and other special machines.

Keep medium and temperature at a distance

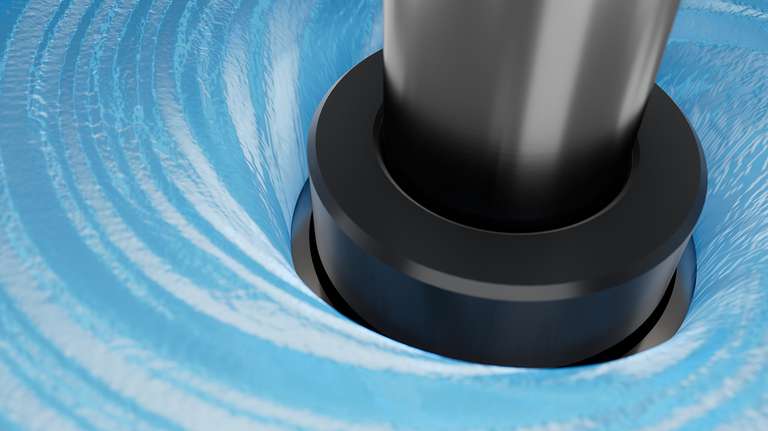

Especially in machines with a side or bottom entry drive, the medium is pressed against the sealing gap, posing unique challenges for the seal design, and increasing the risk of buildup. To solve this problem, EagleBurgmann equipped the HSMR34 and SeccoMix R mechanical seals with a solid counter ring that extends far into the product. In addition to excellent heat dissipation, this also has another advantage: The rotation of the counter ring produces centrifugal forces that keep material from accumulating in the sealing gap.

An O-ring integrated into the solid counter ring separates the shaft from the product, ensuring that the shaft sleeve has no contact with the product and opening up new options for shaft sleeve materials. Both agitator seals are also available in a hygienic design suitable for CIP/SIP.

Robust and reliable

EagleBurgmann optionally offers the mechanical seals with DiamondFace technology for particularly challenging operating conditions. This makes the seal face highly resistant to inadequate lubrication and partial dry running while also ensuring a particle-free operation. Both product lines are ATEX-certified and can be used in all areas at risk of explosion, which is confirmed by a category 1 type examination certificate (zone 0).

Versatile and cost-effective

The HSMR34 and SeccoMix R are based on tried-and-tested product lines and feature a modular design, making them perfect for standardization projects. This allows users to reduce the range of seal types, sizes, and materials to increase availability and simplify the management of replacement parts. The streamlining of installation, maintenance, and servicing work as well as training measures is another key benefit of this modular approach. Both mechanical seals are available with or without bearing.

Sales via EagleBurgmann Germany in Wolfratshausen and all international branches: Tel. +49 8171 23 0, info@eagleburgmann.com, www.eagleburgmann.com

The Eagleburgmann Group

Sealing technology for plants and machines

EagleBurgmann is one of the worldwide leading providers of industrial sealing technology. Mechanical seals, seal supply systems, magnetic couplings, carbon floating ring seals, expansion joints, gaskets and packings as well as comprehensive services are used wherever reliability and safety are needed.

Mechanical seals and more

Sealing technology by EagleBurgmann is used worldwide in oil and gas industries, refineries, the petrochemical, chemical, and pharmaceutical industries, food processing, energy, water, mining, paper, aerospace, and other industries. Close to 5,800 employees provide their ideas, solutions, and commitment so that customers can rely on our sealing technology.

What makes us stand out is our excellent quality, great innovative capacity, and an extensive product portfolio for nearly all industrial processes and fields of application. Our product portfolio includes everything from mechanical seals and seal supply systems to magnetic couplings, carbon floating ring seals, expansion joints, and gaskets and packings as well as comprehensive services. Since we are part of the German Freudenberg and Japanese EKK group, we have all the necessary resources for a firmly based reliable partnership.